| SMART BOILERS OPERATING DATA |

| Marking |

|

400 |

| Nominal power Pn |

kW |

400 |

| Partial load (power) Pp |

kW |

100 |

| Boiler efficiency at Pn |

% |

>95 |

| Boiler class |

|

5 |

| Water volume |

l |

790 |

| Diameter of water connection |

“ |

4 |

| Diameter of water connection |

DN |

100 |

Hydraulic-pressure drop of the boiler

at the temperature fall 20° |

mbar |

110 |

| Boiler temperature |

°C |

60–90° |

| Minimal temperature of returnable water |

°C |

55 |

| Maximal operational pressure |

bar |

3,5 |

| Test pressure |

bar |

6,5 |

| Temperature of furnace |

°C |

900–1100 |

| Pressure of furmace |

mbar |

-0,04 |

| Required draught of the chimney |

mbar |

0,2 |

| Requirement for the forced draught |

|

Yes |

| Combustion temperature at Pn |

°C |

98,9 |

| Combustion temperature at Pp |

°C |

62,7 |

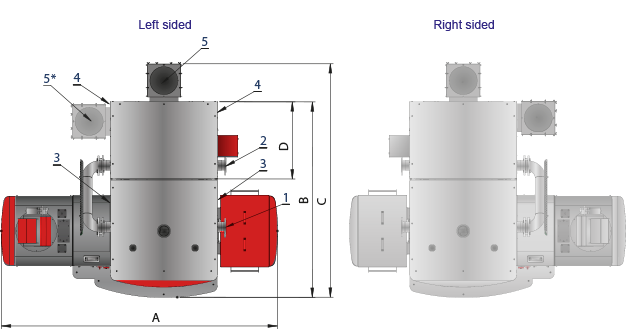

| Diameter of flue gas duct |

mm |

300 |

| Diameter of chimney |

mm |

350 |

| Wood pellets – C1 |

Testedfuel |

D6, M10, A1,5, DU90,0 |

| Wood chips – B1 |

P45, M30, A3.0 |

| Electrical connection |

|

3+N+PE 50Hz 230/400V TN-C-S |

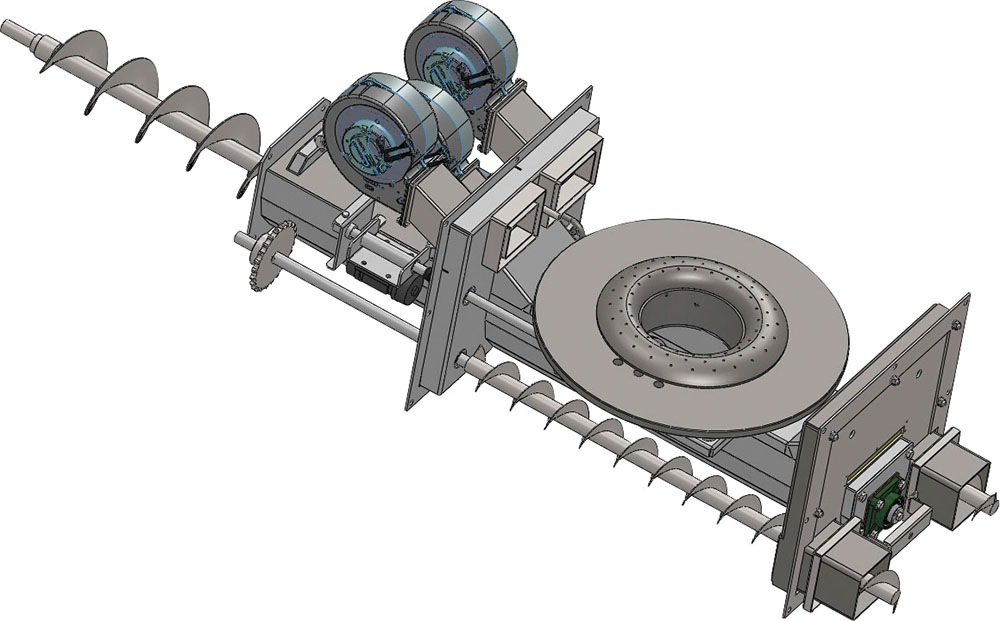

| Conveyor engine |

W |

550 |

| Feeding auger engine |

W |

550 |

| Exchanger cleaning engine (s) |

W |

2 x 550 |

| Ash-removing engine |

W |

550 |

| Fan of primary air |

W |

66 |

| Fan of secondary air 1 |

W |

170 |

| Fan of secondary air 2 |

W |

170 |

| Chimney exhaust fan |

W |

1100 |

| Electrical ignition |

W |

1600 |

| Separation flap valve |

W |

6,5 |

|

| Wood pellets |

Wood chips |

| Rated |

Minimum |

Rated |

Minimum |

| Rated heat capacity |

kW |

400 |

400 |

400 |

400 |

| Combustion producttemperature |

°C |

95,1 |

62,0 |

98,9 |

62,7 |

| Fuel consumption |

kg/hour |

90,70 |

20,60 |

98,30 |

22,90 |

| Input water temperature |

°C |

60,2 |

61,1 |

59,7 |

57,9 |

| Outlet water temperature |

°C |

77,8 |

76,5 |

75,4 |

74,1 |

| Cooling water temperature |

°C |

9,4 |

10,4 |

9,6 |

11,0 |

| Cooling water flow rate |

m3/hod |

19,311 |

5,110 |

22,025 |

5,135 |

| Draught behind boiler |

Pa |

173,0 |

25,0 |

170,0 |

26,0 |

| Ambient temperature |

°C |

27,0 |

24,0 |

28,0 |

24,0 |

| Relative air humidity |

% |

32,0 |

33,0 |

35,0 |

35,0 |

| Barometric pressure |

kPa |

99,10 |

99,30 |

99,05 |

99,15 |

| Oxygen O2 |

% |

8,06 |

9,43 |

7,24 |

10,73 |

| Carbon dioxide CO2 |

% |

11,26 |

10,10 |

11,95 |

9,31 |

| Carbon monoxide CO |

ppm |

105 |

111 |

139 |

167 |

| Higher hydrocarbons OGC |

ppm |

9 |

3 |

2 |

6 |

| Nitrogen dioxides Nox |

ppm |

68 |

67 |

100 |

65 |

| Dust |

mg/m3 |

25 |

29 |

66 |

67 |

| Carbon monoxide CO |

mg/m3 |

116 |

144 |

140 |

227 |

| Higher hydrocarbons OGC |

mg/m3 |

5 |

2 |

1 |

3 |

| Nitrogen dioxides Nox |

mg/m3 |

118 |

130 |

164 |

139 |

| Dust |

mg/m3 |

20 |

29 |

30 |

48 |

| Mass flow rate gases |

kg/sec |

0,276 |

0,068 |

0,257 |

0,074 |

| Stoichiometric oxygen value |

m3/kg |

0,958 |

0,957 |

0,832 |

0,830 |

| Stoichiometric air value |

m3/kg |

4,560 |

4,559 |

3,961 |

3,951 |

| Stoichiometric volumeof dry combustion products |

m3/kg |

4,449 |

4,447 |

3,882 |

3,872 |

| Stoichiometric air multiple |

|

1,62 |

1,85 |

1,52 |

2,08 |

| Volume of dry combustion products, actual |

m3/kg |

7,521 |

8,442 |

6,294 |

8,106 |

| Volume of H2O in the combustion air |

m3/kg |

0,082 |

0,085 |

0,080 |

0,134 |

| Volume of H2O in the combustion produts |

m3/kg |

0,937 |

0,940 |

0,926 |

0,935 |

| Maximum volume CO2 |

% |

19,01 |

19,01 |

19,37 |

19,36 |

| Loss of sensible heat of combustion products (chimney) |

% |

4,8 |

3,0 |

4,7 |

3,2 |

| Loss of gas underburning |

% |

0,1 |

0,1 |

0,1 |

0,1 |

| Loss of mechanical underburning |

% |

0,0 |

0,1 |

0,4 |

0,6 |

| Loss of heat transfer into the environment |

% |

0,5 |

1,1 |

0,5 |

0,9 |

| Total loss |

% |

5,3 |

4,2 |

5,4 |

4,6 |

| Efficiency – indirect method |

% |

94,8 |

95,9 |

94,7 |

95,4 |

| Heat input |

kW |

417,2 |

94,9 |

420,1 |

98,1 |

| Heat capacity |

kW |

398,0 |

91,0 |

401,8 |

94,0 |

| Uncertainty of determining heat capacity |

% +/- |

16,7 |

3,8 |

16,9 |

4,0 |

| Efficiency – direct method |

% |

95,4 |

95,9 |

95,6 |

95,8 |

| Capacity / rated output |

% |

99,5 |

22,8 |

100,9 |

23,9 |

|